Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

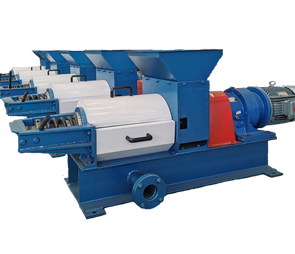

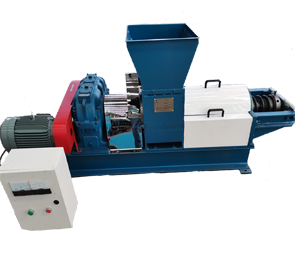

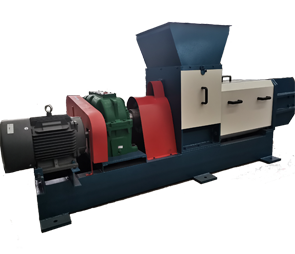

Double screw palm oil press is a typical screw oil press which is widely used in pressing oil from palm fruit. While setting up the palm oil extraction plant, double screw palm oil press machine is an important machine that determines other parameters such as production capacity, and the quality of produce among other business aspects of production.

Processing Capacity: 15TPH

Processing Capacity: 15TPH Residual Oil Rate: ≤7%

Residual Oil Rate: ≤7%

all machine can be customized according to customers' needs.

Double screw palm oil press machines usually used in large, medium and small scale palm oil mill for oil extraction with fresh palm fruits. The most common processing capacity is 3tph, 5tph, 15tph. As for the special processing capacity, we can customize it for you.

The twin-screw oil press is the most mature, stable and best-squeezing product on the market. The oil press uses twin screws that squeeze each other, so that the material is automatically sucked in, the squeezing is uniform, the chamber pressure is high, and the core crushing rate is low. The crude oil contains less residue and the crude oil is easy to clarify and separate. The discharge port uses a hydraulic cylinder to calibrate the cake. The hydraulic system has an automatic control program to adjust the chamber pressure according to the squeezing effect, so as to achieve a better squeezing effect. The hydraulic calibrating system can be operated manually or automatically.

QIE Group is a professional palm oil mill plant machine manufacturer. We can provide palm oil expeller machine, large scale palm oil mill plant, automatic palm oil mill plant, palm oil refinery machine and fractionation plant, turnkey palm oil processing plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing.

| Processing capacity (FFB) TPH | 15 |

| Number of screws | Twin screw, hydraulic compression |

| Spindle speed (r/min) | 10.5 |

| Feed temperature ℃ | 90-95 |

| Cake residual oil (%) | ≤7 |

| Palm kernel damage rate (%) | ≤10 |

| Motor power (kw) | 30 |

| Hydraulic pump station motor power (kw) | 1.5 |

| Dimensions (mm) | 4450×1650×960 |

| Weight(kg) | 4500 |

Years of development have brought customers from all over the world. Contact us to start customizing a palm oil production line for your business.

Our palm oil production equipment has been exported to more than 120 countries and regions, and many customers have established long-term cooperative relationships with us. Below are some of the palm oil production equipment and palm oil production lines we manufacture. Whether you need a single feed production equipment or a complete feed production line, we can customize it for you.

Country : Peru

Production Output : 20TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Philippines

Production Output : 40TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Mexico

Production Output : 30TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Cote d’Ivoire

Production Output : 160TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Indonesia

Production Output : 120TPD

Raw Materials : Palm Fruit, Palm Kernel.

Country : Thailand

Production Output : 100TPD

Raw Materials : Palm Fruit, Palm Kernel.

The main components include:

Sterilizer: Steam-heats FFB to soften the fruits and deactivate enzymes.

Thresher/Digester: Separates fruits from bunches and breaks them into pulp.

Screw Press: Extracts oil from the pulp under high pressure.

Clarifier: Purifies the crude oil by removing water and impurities.

Refinery: Further processes the oil to meet food-grade standards (optional).

Electric motors (for small/medium units, 5–30 HP).

Diesel engines (in areas with unstable electricity).

Steam boilers (for sterilization in large mills).

Small-scale: 1–5 tons of FFB per day (suitable for rural farms).

Medium-scale: 10–50 tons/day (for cooperatives).

Industrial-scale: 50–100+ tons/day (large mills).

Key benefits include higher oil yield efficiency, reduced labor costs, improved oil quality, and faster production compared to manual methods.

Low oil yield: Caused by unripe fruits or improper machine settings.

High free fatty acids (FFA): Due to delayed processing or poor sterilization.

Machine breakdowns: Often from overloading or lack of maintenance.

Daily: Clean residues, check bolts/nuts, and lubricate moving parts.

Weekly: Inspect belts, bearings, and press screws for wear.

Monthly: Replace worn-out parts (e.g., press cages, filters).

It integrates sterilization, threshing, pressing, clarification, and refining stages to process fresh fruit bunches (FFB) into edible oil, typically featuring automated material handling between equipment modules.

Palm oil is an edible vegetable oil extracted from the fruit of African oil palm trees (Elaeis guineensis). It dominates global vegetable oil consumption due to its unique properties: semi-solid at room temperature, oxidation resistance, and versatility in both food and non-food applications. This makes it ideal for extending shelf life in packaged goods.

QIE Machinery is a large-sizd joint-equity enterprise specializing in the production of palm oil mechanical equipment. It integrates scientific research, manufacturing and sales, and provides complete set of equipment for palm oil and palm kernel oil production. Customize the palm oil processing equipment capacity according the different customers requirements.