Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

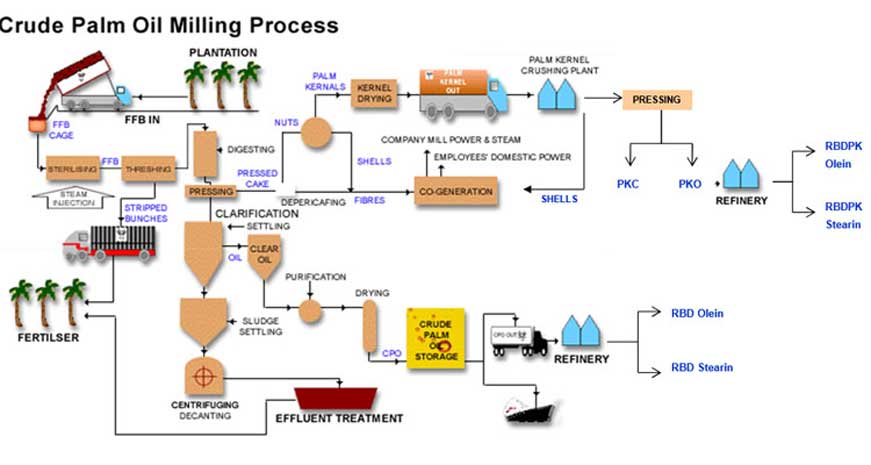

Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process. The main process of the palm oil factory includes:sterilization, threshing,pressing, clarification, purification, drying and storage. For the kernel line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil.

Brand

QIE

Raw Material

Palm Fruit,Palm Kernel

Capacity

1-120TPH

1-120TPH

Customized Palm Oil Processing Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 5 ton/d up to 1000 ton/day

Degumming Process

The oil degumming process aims to remove the gum impurities in crude palm oil to make it suitable for further refinery processes. Water or acid is added to remove phospholipids and gums.

Deacidification Process

Oil Deacidification is a process that has a great impact on palm oil quality. If there is a problem with the neutralization process, the following decoloration will be greatly affected. The free fatty acid in crude palm oil can affect the stability and relish of palm oil.

Bleaching Process

The palm oil bleaching process is to remove oil pigment, residual soap, and metal ions. The bleaching process can improve the oil color, relish, and increase the oxidation stability, thus providing a good condition for the deodorization process.

Deodorization Process

Steam distillation removes volatile components that cause odors. The palm oil deodorization section plays an important role in improving palm oil quality. The refined palm oil is nearly colorless and transparent in the liquid state and white in the solid state.

Dry palm oil fractionation is the most economical fractionation without adding any solvent. The oil in dissolved state is cooled slowly to a certain degree, passing through filtration to separate crystals and precipitate solid ester. Production Capacity:50-1000TPD

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

Learn MoreReception and cleaning: FFBs are unloaded, sorted to remove debris, and washed to eliminate dirt.

Sterilization: FFBs are steamed at high temperatures (120–140°C) to stop enzyme activity, soften the fruit, and loosen it from the bunch.

Threshing: Sterilized bunches are mechanically beaten to separate palm fruits from the empty bunches.

Digestion and pressing: Fruits are crushed (digested) to break cell walls, then pressed to extract a mixture of crude palm oil, water, and solids.

Clarification: The pressed mixture is heated and centrifuged to separate CPO from water and impurities.

Kernel recovery: The remaining solid waste (palm press fiber) is processed to extract palm kernels, which undergo their own crushing and oil extraction for PKO.

Refining (optional): For edible use, CPO may be refined through degumming, neutralization, bleaching, and deodorization to remove free fatty acids, pigments, and odors.

Production capacity varies widely based on plant size. Small-scale plants may process 1–10 tons of FFBs per hour, yielding roughly 10–100 tons of CPO daily (since FFBs contain about 20–25% oil by weight). Medium to large-scale plants can handle 30–100 tons of FFBs per hour, producing 300–1,000 tons of CPO daily. Some industrial facilities in major palm oil-producing countries (e.g., Indonesia, Malaysia) process over 2,000 tons of FFBs per hour, with corresponding CPO outputs exceeding 500 tons daily.

Empty Fruit Bunches (EFBs): Used as biomass fuel for steam generation, compost, or raw material for paper, fiberboards, or biogas production.

Palm Press Fiber (PPF): A fibrous residue used as fuel in boilers or as animal feed additive (after processing).

Palm Kernel Cake (PKC): A protein-rich by-product from kernel oil extraction, used as livestock feed.

Palm Fatty Acid Distillate (PFAD): A by-product of refining, used in soap making, biodiesel, or as a feed supplement.

Sludge oil: Recovered from wastewater treatment, it can be processed into low-grade fuel or industrial oils.

Reception equipment (conveyors, weighbridges, cleaning screens).

Sterilizers (vertical or horizontal steam chambers).

Threshers (rotary drum or hammer mills) to separate fruits from bunches.

Digesters (mechanical crushers) and screw presses for oil extraction.

Clarifiers (decanters or centrifuges) to separate oil from water and solids.

Kernel recovery machines (screeners, crushers, separators).

Boilers (for steam generation, often biomass-fired).

Storage tanks (for FFBs, CPO, kernels, and by-products).

For refining: degumming tanks, neutralization vessels, bleaching filters, and deodorizers.

Crude Palm Oil (CPO): Extracted directly from palm fruits, it is unrefined, with a reddish color (due to carotenoids), a distinct odor, and contains impurities like free fatty acids, moisture, and solids. It is primarily used as a feedstock for refining or in industrial applications.

Refined Palm Oil: Produced by processing CPO to remove impurities. Refining steps (degumming, neutralization, bleaching, deodorization) eliminate free fatty acids, pigments, and odors, resulting in a pale, odorless oil. It is suitable for edible uses (cooking, baking, food processing) and meets food safety standards for human consumption.

FFB quality: Ripe, undamaged FFBs yield higher-quality oil; overripe or spoiled bunches increase free fatty acids.

Processing conditions: Proper sterilization (temperature, time) prevents enzymatic degradation; efficient pressing maximizes oil extraction.

Clarification efficiency: Inadequate separation of oil from water/solids can introduce impurities.

Storage: CPO stored in clean, sealed tanks avoids oxidation or contamination; exposure to heat or light degrades quality over time.

Compliance with processing standards (e.g., moisture content below 0.5%, free fatty acid levels below 5% for CPO) also impacts marketability.

FFB supply and quality: Dependence on consistent, high-quality FFBs, which can be affected by weather, crop yields, or transportation delays.

Cost management: Fluctuating energy and labor costs, especially for plants reliant on external fuel sources.

Environmental regulations: Strict rules on wastewater treatment, emissions, and waste disposal, requiring investment in green technologies.

Market volatility: Price fluctuations for CPO and by-products, influenced by global demand, trade policies, and sustainability certifications (e.g., RSPO).

Technology upgrades: Keeping up with efficient, low-waste processing technologies to remain competitive and meet sustainability goals.