Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

We can offer turnkey palm oil refinery plant solutions from plant layout design, machinery manufacturing, onsite debugging and installing. The production capacity ranges from 1 ton/d up to 1000 ton/day. Send ~us an inquiry if you are interested in start palm oil refining line or factory. We are always glad to give suggestions for your business!

Brand

QIE

Raw Material

Crude Palm Oil

Capacity

Minimum 1TPD

1-1000TPD

Customized Palm Oil Refinery Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

The refining of palm oilcould be processed either physical or chemical refining route. Due to cost effectiveness and high FFA of palm oil its generally used physical refining route. Production Capacity: 1-1000TPD

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

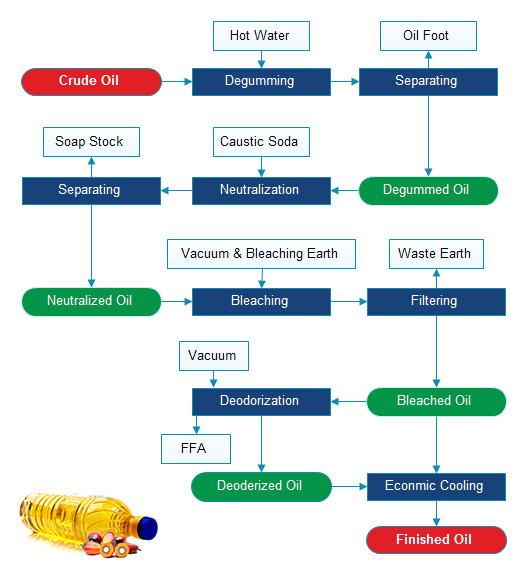

Learn MoreDegumming: Removes phospholipids (gums) by adding water or acid, which cause the gums to precipitate and separate from the oil. This step improves the oil’s stability and prevents cloudiness.

Neutralization: Uses alkaline solutions (e.g., sodium hydroxide) to react with free fatty acids (FFAs), forming soap stocks that are then removed. This reduces acidity and enhances the oil’s flavor.

Bleaching: Treats the oil with adsorbents like activated clay or charcoal to remove pigments (e.g., carotene) and residual impurities, lightening the oil’s color.

Deodorization: Applies high temperatures (200–250°C) under vacuum to evaporate volatile compounds responsible for odors and remaining FFAs. This step also destroys any remaining microorganisms.

Fractionation (optional): Separates RBD palm oil into liquid olein and solid stearin using controlled cooling and filtration, creating products with specific melting points for diverse applications (e.g., cooking oils, margarine).

Palm oil refineries generate several by-products and waste streams, which are managed through targeted processes to minimize environmental impact and maximize resource use:

Soap stocks from neutralization are processed to recover fatty acids, which are used in soap, detergent, or animal feed production.

Palm fatty acid distillate (PFAD) from deodorization is rich in fatty acids and vitamin E; it is used in biofuels, cosmetics, or as a feed additive.

Spent bleaching earth (used adsorbents) may be treated to extract residual oil before being disposed of safely or repurposed as a soil amendment.

Wastewater containing organic matter is often treated in biological wastewater treatment plants to reduce pollutants before discharge or reuse for irrigation.

Some refineries also explore energy recovery, such as burning non-recyclable waste to generate heat for the refining process.

Quality of crude palm oil (CPO): CPO with high FFA levels, moisture, or impurities requires more intensive processing, increasing energy and chemical use.

Equipment design and maintenance: Modern, well-maintained machinery (e.g., efficient centrifuges, heat exchangers) reduces energy loss and downtime. Poorly maintained equipment may cause leaks, uneven processing, or product contamination.

Process parameters: Precise control of temperature, pressure, and chemical dosages (e.g., in neutralization or bleaching) ensures optimal impurity removal without over-processing, which wastes resources.

Energy and water management: Use of energy-efficient technologies (e.g., heat recovery systems) or recycled water reduces operational costs and environmental impact.

Skilled labor: Trained operators can adjust processes in real time to address issues like fluctuations in CPO quality, preventing inefficiencies.

Its high smoke point (around 230°C) makes it ideal for frying, baking, and high-temperature cooking, as it resists oxidation and breakdown.

Its neutral flavor and stability (due to low unsaturated fatty acids) make it a common ingredient in processed foods like snacks, baked goods, and margarine.

However, its semi-solid consistency at room temperature (due to high saturated fat content) limits its use in products requiring liquid oils at cool temperatures, such as salad dressings. For such uses, fractionated palm olein (liquid at room temperature) is preferred.

Additionally, some consumers or manufacturers may avoid it due to concerns about sustainability (e.g., deforestation linked to palm cultivation) or nutritional debates, though it is widely approved for food use by regulatory bodies like the FDA and EFSA.

Fire and explosion prevention: Installing fire suppression systems (e.g., sprinklers), ensuring proper ventilation in areas with volatile compounds, and using non-sparking equipment to avoid igniting flammable fumes.

Chemical handling: Storing alkaline solutions and acids in secure, labeled containers with spill containment systems. Workers must use protective gear (gloves, goggles, suits) to prevent chemical burns.

Pressure and temperature control: Using pressure relief valves and automated monitoring systems to prevent overheating or pressure buildup in deodorizers and distillation units, which could cause equipment failure.

Worker training: Regular safety drills, training on emergency protocols (e.g., chemical spills, fires), and certification for operating machinery.

Hygiene standards: Sanitized equipment and processing areas to prevent microbial contamination, ensuring compliance with food safety regulations (e.g., HACCP).

High FFA and moisture in CPO: Crude palm oil often has higher FFA levels than other crude oils, requiring more aggressive neutralization. It also contains more moisture, making degumming critical to avoid hydrolysis during processing.

Pigment removal: Palm oil is rich in carotene (giving it a deep red-orange color), so bleaching requires more adsorbent or longer processing time compared to lighter oils like sunflower oil.

Fractionation: Unlike most oils, palm oil is frequently fractionated into olein and stearin due to its balanced ratio of saturated and unsaturated fats, creating products with distinct melting points. This step is less common for oils like olive or canola.

Thermal stability: Palm oil’s high saturated fat content makes it more resistant to heat, reducing the risk of oxidation during deodorization compared to polyunsaturated oils, which require gentler conditions.

Energy use: Refining is energy-intensive, especially for deodorization and fractionation. Using renewable energy (e.g., biomass from palm waste) or energy-efficient equipment reduces carbon emissions.

Water consumption: Processing requires significant water for degumming and cleaning. Wastewater must be treated to remove oils, fats, and chemicals to prevent water pollution. Some plants reuse treated water for non-potable purposes.

Emissions: Volatile organic compounds (VOCs) from deodorization or boiler exhaust can contribute to air pollution. Installing scrubbers or catalytic converters helps reduce harmful emissions.

Sustainability certifications: Many refineries seek certifications like RSPO (Roundtable on Sustainable Palm Oil) to ensure they source CPO from environmentally responsible suppliers, avoiding deforestation-linked palm oil.

Waste reduction: Minimizing waste through by-product recycling (e.g., PFAD to biofuels) reduces the need for landfills and aligns with circular economy goals.

Free Fatty Acids (FFAs): Typically below 0.1% in RBD palm oil, as high FFAs cause rancidity and off-flavors.

Moisture and impurities: Less than 0.1% moisture to prevent microbial growth; impurities (e.g., dirt, sediment) must be undetectable.

Color: Light yellow to pale gold (measured using a Lovibond scale), with minimal residual pigments.

Peroxide value: Below 10 meq/kg, indicating low oxidation and good stability.

Smoke point: Minimum 230°C for frying applications, ensuring it resists breakdown at high temperatures.

Compliance with regulations: Adherence to standards set by bodies like the FDA (U.S.), EFSA (EU), or Codex Alimentarius, which may restrict contaminants like heavy metals or pesticides.

Automation and AI: Real-time monitoring systems (e.g., sensors for FFA levels, color) and AI-driven process control adjust parameters automatically, reducing human error and ensuring consistent output.

Energy-efficient equipment: Heat recovery systems capture waste heat from deodorization to preheat crude oil, cutting energy use by up to 30%. Low-pressure deodorization techniques also reduce energy consumption.

Eco-friendly processing: Use of biodegradable chemicals in degumming or natural adsorbents (e.g., rice husk ash) in bleaching reduces environmental impact. Enzymatic degumming is being tested as a greener alternative to traditional methods.

By-product valorization: Advanced extraction techniques recover more valuable compounds from by-products, such as natural vitamin E (tocopherols) from PFAD for use in supplements or cosmetics.

Sustainability tracking: Blockchain technology helps trace CPO origins, ensuring refineries source from certified sustainable suppliers and meet transparency requirements.