Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Small scale palm oil mill can be customized for 1 ton/hour, 2 ton/hour, 3 ton/hour, and 5 ton/hour input. 1-5TPH small palm oil processing mill is composed of vertical sterilization tank, drum thresher, crushing tank, double-screw palm oil press, oil clarification equipment and other equipment, with high efficiency and low energy consumption , high degree of automation and so on.

Brand

QIE

Raw Material

Palm Fruit,Palm Kernel

Capacity

Minimum 1TPH

1-5TPH

Customized Small Scale Palm Oil Processing Plant On Demand

Highly Intelligent Production In All Sections

Intelligent

A small palm oil refinery plant is a facility that processes crude palm oil into refined, edible palm oil, suitable for various applications. These plants are designed for smaller-scale operations, often with a capacity ranging from 1 to 20 tons per day.

QIE Grain and Oil Machinery Co., Ltd

With decades of expertise,QIE Machinery has successfully installed palm oil production lines worldwide, serving customers in over 100 countries. Our extensive product portfolio includes palm fruit and palm kernel oil production solutions, as well as customized solutions for specific capacities ranging from small-scale operations to large conglomerate production facilities.

Whether in Asia, Europe, the Americas or Africa, our equipment is tailored to meet local market needs and production challenges. We operate worldwide and customer satisfaction is at the heart of every project we undertake. From initial consultation and design to installation and after-sales service, QIE Machinery ensures that every solution meets the highest standards of quality and efficiency.

Get Quote

This efficient 20 TPD palm oil refining and fractionation plant was built in Peru to produce high quality edible palm oil.

Learn More

This project is located in Philippines. We are in charge of project design, equipment manufacturing and the guidance of installation and commission.

Learn More

This 30TPD palm oil refining project is located in Mexico. This customer has visited many factories before working with us and has a very thorough understanding of the palm oil refining industry.

Learn More

This project is located in Cote d'Ivoire. Mainly Process: Loading, Sterilizing, Threshing, Pressing, Fiber separation, Kernel recovery, Oil Clarify.

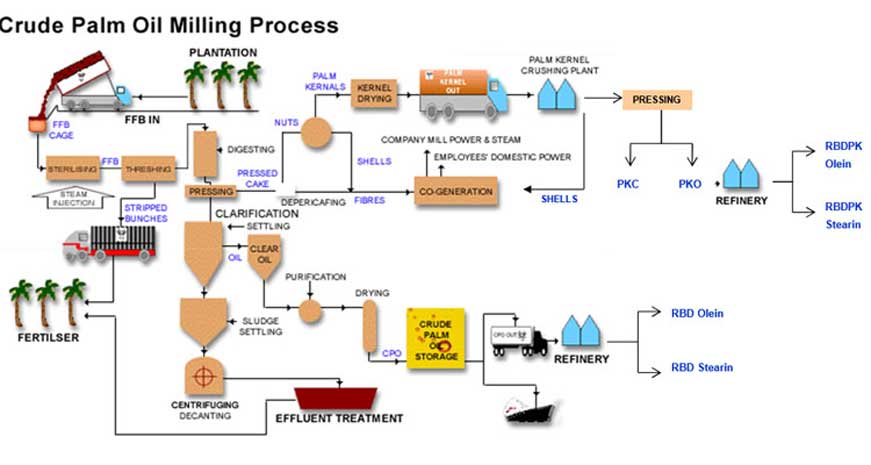

Learn MoreFor palm fruit to crude palm oil:

Fruit reception: Palm fruit bunches are received from plantations and transported to the sterilizer.

Sterilization: A vertical palm fruit sterilizer is commonly used. Direct steam is applied to process the palm fruit. This inactivates enzymes, preventing rancidity and ensuring good - quality crude oil. It also aids the threshing process.

Threshing: Separates the empty fruit bunches from the palm fruit. Different types of threshers, such as simple - type or drum - type, can be used depending on the production scale.

Pressing: The sterilized palm fruit is conveyed to a digestor, where blades roll to break the fruit. Then, a palm oil press is used to extract palm oil from the pulp. Multiple pressing processes may be used to minimize kernel breakage, as broken palm kernel oil can contaminate the crude palm oil and affect its quality.

Purification and clarification: The mixture of crude palm oil, water, and small solid particles is clarified. Traditional methods involve gravity separation.

For refining crude palm oil:

Degumming: Removes phospholipids and other gums from the crude oil.

Neutralization (de - acidification): Alkali is used to neutralize free fatty acids (FFA) in the crude oil.

Bleaching (de - colorization): Removes pigments from the oil, usually using materials like activated carbon or white clay.

Deodorization: Removes off - flavors and volatile compounds from the oil.

For palm fruit processing:

Palm fruit sterilizer: Vertical sterilizers are common for Small scale plants.

Palm fruit thresher: Available in simple and drum - type models.

Digestor: Breaks open the palm fruit to facilitate oil extraction.

Palm oil press: Can be a single - screw or double - screw press, depending on the scale and efficiency requirements.

Oil clarification equipment: Such as plate - and - frame filter presses for separating oil from impurities.

For palm oil refining:

Refining pot: Used for degumming and neutralization.

Decolorization pot: Equipped with a means to introduce bleaching agents like white clay.

Deodorization pot: Usually operates under vacuum and high - temperature conditions.

Conductive oil stove: Provides heat for the overall refining process.

Vacuum pump: Creates a vacuum for decolorization and deodorization.

Air compressor: Dries the white clay after it absorbs pigments.

Steam generator: Supplies steam for the deodorization pot.

A Small scale palm oil processing plant with a capacity of 1 - 5 tons per hour may require a relatively compact space. The processing area for palm fruit to crude palm oil production might need around 50 - 100 square meters, depending on the complexity of the equipment layout. For a Small scale palm oil refinery plant with a capacity of 1 - 10 tons per day, the refining unit can be installed in an area of about 50 square meters. However, additional space should be allocated for storage of raw materials (palm fruit or crude oil), finished products, and for maintenance and movement of equipment.

Proximity to raw materials: It is crucial to be near palm plantations to obtain fresh palm fruit. Long - distance transportation of palm fruit can increase the acid value of the resulting crude palm oil due to enzymatic reactions.

Infrastructure: Adequate water and power supply are essential. The power supply should be stable to run the processing equipment. Also, good road connectivity is needed for the transportation of raw materials and finished products.

Environmental conditions: The location should be free from excessive humidity, flooding, and strong winds that could damage the equipment. It should also comply with local environmental regulations regarding waste disposal.

Labor availability: There should be a sufficient local labor force to operate the plant. Training facilities for workers should also be accessible or easy to set up.

The cost varies widely depending on factors such as capacity, equipment quality, and location. For a basic Small scale palm fruit processing plant with a capacity of 1 - 5 tons per hour, the equipment cost can range from hundreds of thousands to over a million dollars. This includes the cost of sterilizers, threshers, presses, and clarification equipment. For a Small scale palm oil refinery plant with a capacity of 1 - 10 tons per day, the equipment cost can be in a similar range, considering the cost of refining, decolorization, and deodorization equipment. In addition to equipment, costs for land acquisition (if not already owned), building construction (if required), transportation, installation, and commissioning should be factored in. There are also ongoing costs such as raw material purchase, labor, and maintenance.

When proper processing techniques and equipment are used, Small scale palm oil processing plants can produce high - quality palm oil. In the palm fruit - to - crude - palm - oil stage, following the correct sterilization, threshing, pressing, and clarification steps can yield crude palm oil with a low level of impurities. During the refining process, if degumming, de - acidification, de - colorization, and deodorization are carried out effectively, the refined palm oil can meet national and international quality standards. However, inconsistent processing, use of sub - standard equipment, or lack of proper maintenance can lead to lower - quality palm oil with higher levels of impurities, off - flavors, or discoloration.

Regular cleaning: All equipment, especially the processing vessels (sterilizers, refining pots, etc.), should be cleaned regularly to prevent the build - up of oil residues, which can affect the quality of the processed palm oil and cause equipment corrosion.

Inspection of moving parts: Parts such as conveyor belts, motors, and blades in threshers and digestors should be inspected regularly for signs of wear and tear. Worn - out parts should be replaced promptly.

Lubrication: Moving parts should be lubricated according to the manufacturer's recommendations to reduce friction and extend the lifespan of the equipment.

Calibration: Equipment such as pumps, flow meters, and temperature sensors should be calibrated regularly to ensure accurate operation.

Professional maintenance: Periodically, a professional technician should be hired to conduct a comprehensive inspection of the entire plant, including electrical systems, steam lines (if applicable), and mechanical components.