Palm oil is one of the most versatile ingredients in the world, found in everything from shampoo and toothpaste to cakes and coffee creamer.

But how is palm oil made?

Palm oil production begins with palm oil seeds. As oil palms have a productive life of 25-30 years, the choice of seeds will impact production for decades to come. Asian Agri has developed its own Topaz seeds, which produce higher yields and are more resistant to pests than regular oil palms, increasing productivity of oil palm plantations.

The seeds are planted in a nursery where they receive daily watering and upkeep for the first eight months of their life, before being transplanted to the plantations.

In the plantations the trees are watered and treated with fertiliser as needed while they grow. After 30 months they are considered mature and are ready for their first harvest, a process that will be repeated every 7-10 days.

Palm oil fruit grow in dense bunches known as Fresh Fruit Bunches (FFB). To harvest the FFB, the harvester uses a long sickle to remove it from the palm tree. FFB which are ready to be harvested can be easily identified due to the bright red-orange colour of their palm fruit.

Palm Oil Production Process

Palm oil production involves a series of steps from cultivating oil palm trees to processing the fruit into usable oil. Here’s a step-by-step breakdown of how palm oil is made:

Oil palm trees (Elaeis guineensis) thrive in tropical climates (e.g., Southeast Asia, Africa, South America) with high rainfall and temperatures. They take 3–4 years to mature and start producing fruit clusters (called “bunches”) that weigh 10–40 kg. A mature tree yields 10–30 bunches annually, with each bunch containing 1,000–3,000 individual fruits.

Ripe fruit bunches are harvested when the fruits turn bright red/orange (typically 5–6 months after flowering). Harvesters use machetes or pole saws to cut bunches from the tree, ensuring they don’t damage the tree’s trunk (to allow future growth).

Freshly harvested bunches are quickly transported to a processing mill to prevent spoilage. The first step is sterilization: bunches are steamed at high pressure (120–140°C) for 30–60 minutes. This:

- Stops enzyme activity (which would break down oil and cause fermentation).

- Loosens the fruits from the bunch.

- Softens the fruit flesh to ease oil extraction.

After sterilization, the bunches are fed into a threshing machine, which separates the individual fruits from the bunch stalks. The stalks are discarded or used as fuel/fertilizer.

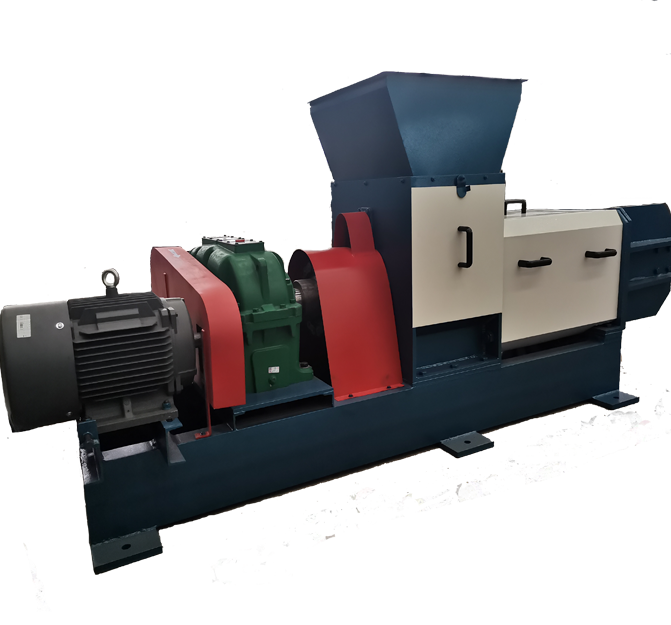

The separated fruits are crushed and “digested” (macerated) using mechanical crushers or heated digesters. This breaks down the fruit’s cell walls, releasing the oil.

The mixture (crushed fruit + oil + water) is then pressed using screw presses. This separates the crude palm oil (CPO) from the solid residue (fibers and kernels).

The pressed oil is a mixture of oil, water, and impurities (e.g., dirt, small fibers). It’s heated to 80–90°C and centrifuged or filtered to separate the oil from water and solids. The result is crude palm oil (CPO), which is reddish-orange due to its high content of carotenoids (vitamin A precursors).

Crude palm oil may undergo further refining to remove impurities, making it suitable for cooking, food processing, or cosmetics:

- Degumming: Removes phospholipids (gums).

- Neutralization: Uses alkali to remove free fatty acids (reducing acidity).

- Bleaching: Uses clays to remove pigments (e.g., carotenoids), resulting in a pale yellow oil.

- Deodorization: Steam distillation removes volatile compounds (improving odor and stability).

Refined palm oil is called RBD (Refined, Bleached, Deodorized) palm oil.

RBD palm oil can be fractionated (separated by melting point) into:

- Palm olein: Liquid at room temperature (used for frying, cooking oils).

- Palm stearin: Solid at room temperature (used in margarine, chocolates, or as a substitute for cocoa butter).

In summary, palm oil production starts with growing oil palm trees, harvesting ripe fruit bunches, extracting crude oil via sterilization, threshing, pressing, and clarification, followed by optional refining and fractionation for specific uses.

Palm oil is used in many products as it is versatile and commercially economical to use. The following products are just some of the products likely to contain palm oil:

- Bread. Crisps. Soaps. Ice Cream. Shampoo. Chocolate. Biscuits. Makeup.

Seizing Success : Path to Effective Palm Oil Production Business

Starting a palm oil production business is a promising opportunity with the potential for significant profits. With the continuous growth in Africa’s population, the demand for palm oil is increasing, making it an opportune time to enter this industry.

The relatively low initial investment makes it accessible for a wide range of entrepreneurs. By getting involved in this thriving business, individuals can not only meet the rising demand for palm oil but also position themselves for substantial financial gains.

We are committed to excellence in the field, and stand ready to support you at every step. With a track record of providing top-notch palm oil processing equipment, tailored solutions, and impeccable services, we ensure your venture is set up for success.

Choose Nandt Engitech as your trusted partner, and let’s cultivate success together in the flourishing palm oil industry.