Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

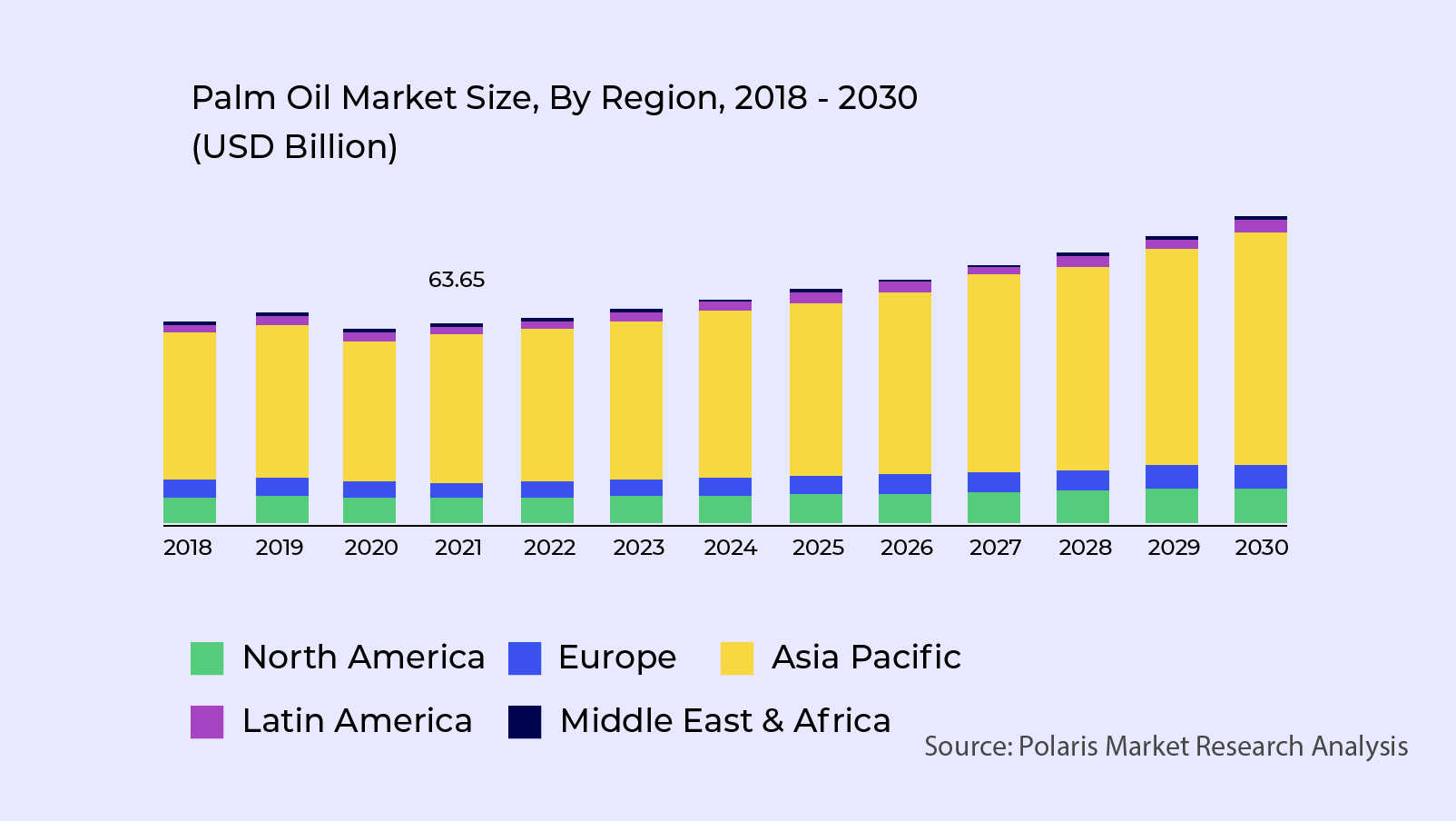

The palm oil sector is poised for growth in 2025, with benchmark crude palm oil (CPO) prices projected to average RM 4,222.7 per metric ton (USD 942.77), up 4.5% from 2024 . This upward trend is fueled by rising biodiesel mandates, especially in Indonesia (B40) and Malaysia, as well as robust edible oil consumption in India and China . Global production is expected to reach 80.34 million metric tons in 2024–25, driven by improved yields and stable supply from major producers .

Setting up the best palm oil refining plant is a complex and multifaceted process that requires careful planning, compliance with regulations, investment in technology, and attention to sustainability. A comprehensive guide to setting up the best palm oil refining plant should encompass the following key steps: market research and feasibility analysis, site selection, design and engineering, machine procurement and installation, and quality control and monitoring.

The palm oil refining process is designed to transform crude palm oil (CPO) into a high-quality, stable, and edible product by removing impurities, undesirable components, and off-flavors. The key steps are as follows:

Crude palm oil (CPO) typically contains mechanical impurities (e.g., dirt, fiber fragments), water, and suspended solids. This step removes these via:

Crude palm oil contains phospholipids (gums), which can cause cloudiness, oxidative instability, or off-flavors in the final product. Degumming removes these by:

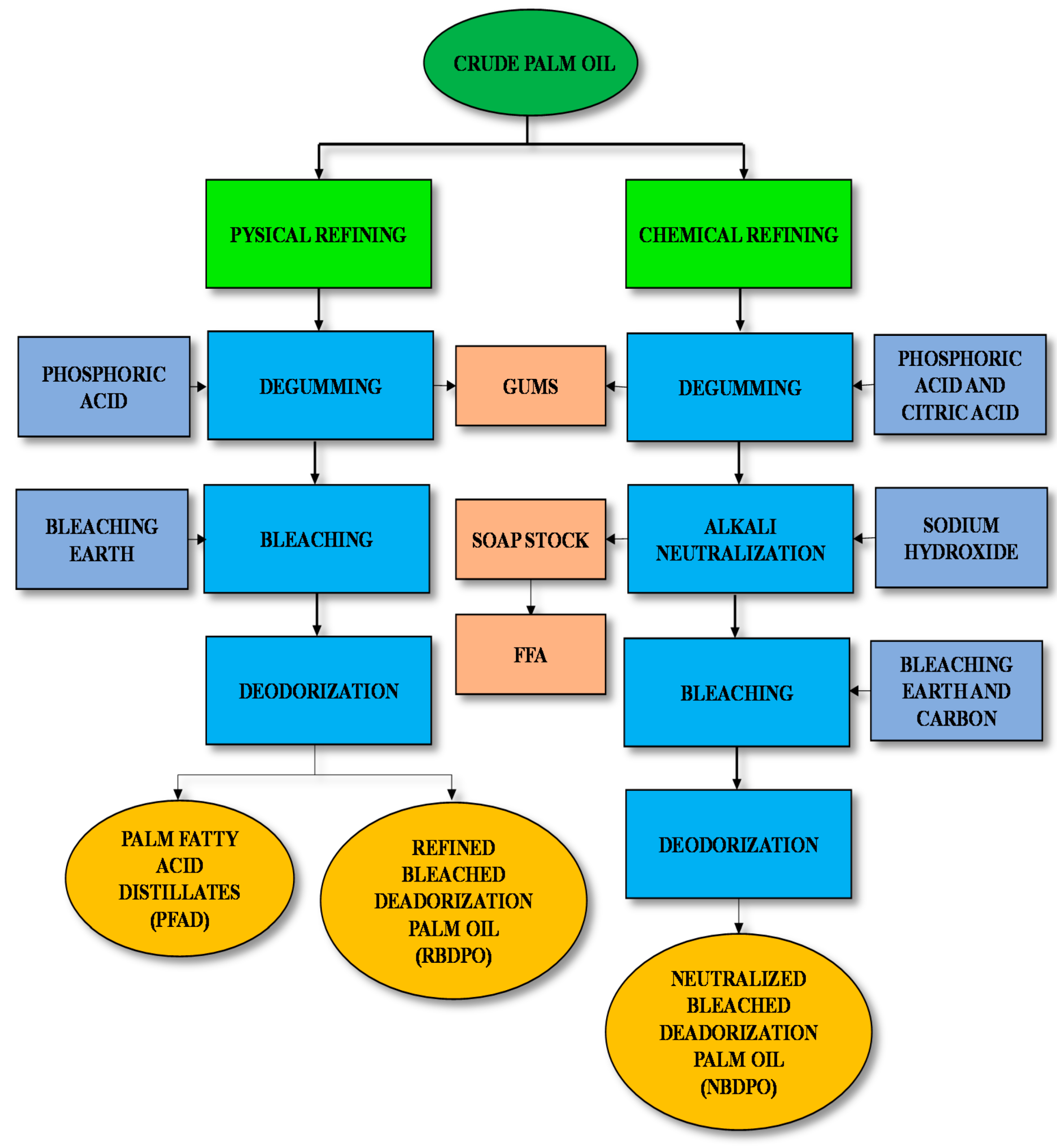

This step targets free fatty acids (FFAs), which contribute to acidity, rancidity, and poor flavor. Two main methods are used:

Residual pigments (e.g., carotenoids, chlorophyll) and trace impurities (soap, metals) are removed to improve color and stability:

Volatile off-flavor compounds (e.g., aldehydes, ketones, short-chain fatty acids) are removed to enhance taste and shelf life:

Palm oil is a mixture of triglycerides with different melting points. Fractionation separates it into:

Fractionation is done via controlled cooling to crystallize stearin, followed by filtration or centrifugation to separate the fractions.

The refined palm oil produced is clear, odorless, and stable, meeting food-grade standards for various applications.

Setting up a palm oil refinery plant involves refining crude palm oil (CPO) into refined, bleached, and deodorized (RBD) palm oil, which is used in food products, biodiesel, cosmetics, and more. The process differs from palm kernel oil refining due to CPO’s unique composition (higher carotenoids, specific fatty acids) and market requirements.

Below is a step-by-step guide:

Start with a thorough assessment to validate the project:

1.Market Demand: RBD palm oil is a staple in food processing (frying oils, margarine, snacks), biodiesel (as a feedstock), and cosmetics. Research local/global trends (e.g., demand for sustainable palm oil, biodiesel mandates) and competition.

2.Raw Material Availability: CPO is derived from palm fruit (Elaeis guineensis). Ensure proximity to palm oil mills or reliable CPO suppliers (local plantations or importers). Assess CPO quality (free fatty acids/FFA, moisture, impurities) and price volatility.

3.Cost-Benefit & ROI: Calculate capital costs (land, equipment) and operational costs (CPO, labor, utilities). Project revenue based on production capacity and market prices.

4.Regulatory & Sustainability: Understand local laws (environmental permits, food safety) and global standards (e.g., RSPO—Roundtable on Sustainable Palm Oil—critical for exports to EU, U.S., etc.).

Choose scale based on market demand and investment:

CPO refining removes impurities (gums, FFAs, pigments, odors) to produce RBD palm oil. Key steps:

Filtration: Remove mechanical impurities (fruit fibers, dirt) using pressure filters or centrifuges.

Heating: CPO solidifies at <24°C, so heat to 40–50°C to maintain liquidity during processing.

Removes phospholipids (gums) that cause cloudiness.

Add water or dilute phosphoric acid to hydrate gums, then separate via centrifugation. CPO has lower phosphatides than other oils, making this step less intensive.

Reduces FFAs (critical for stability). Palm oil often uses physical refining (vs. chemical) due to low gum content:

Physical Refining: Heat oil to 220–260°C under high vacuum (≤5 mmHg) and inject steam to strip FFAs, which are condensed and sold as by-products (used in soap making).

Chemical Refining: (Rare for CPO) Add alkali (sodium hydroxide) to react with FFAs, forming soapstock (separated via centrifugation).

Remove pigments (carotenoids, which give CPO a red/orange hue) and residual impurities (soaps, metals).

Mix oil with adsorbents (activated clay, silica) at 90–120°C under vacuum, then filter out spent adsorbents. Result: pale yellow oil.

Eliminate volatile compounds (odors, aldehydes) to extend shelf life.

Heat oil to 200–250°C under high vacuum while injecting steam to strip volatiles. Use heat recovery systems (e.g., heat exchangers) to reduce energy use.

RBD palm oil is fractionated into:

Palm Olein: Liquid at room temperature (used in frying oils, biodiesel).

Palm Stearin: Solid (used in shortenings, margarine, candles).

Process: Cool oil to 20–25°C to crystallize stearin, then separate via filtration or centrifugation.

Choose equipment based on scale (batch vs. continuous):

| Process Step | Key Equipment |

|---|---|

| Pre-treatment | Heating tanks, pressure filters, decanters. |

| Degumming | Mixing vessels, disc-stack centrifuges. |

| Neutralization/Refining | Physical refining columns, vacuum pumps, steam injectors. |

| Bleaching | Bleaching reactors (with agitators), vacuum systems, filter presses. |

| Deodorization | Deodorization towers, heat exchangers, vacuum pumps, steam generators. |

| Fractionation (optional) | Crystallizers, chillers, membrane filters or centrifuges. |

| Utilities | Boilers (steam from biomass—e.g., palm empty fruit bunches/EFB), wastewater treatment. |

Source from trusted suppliers (e.g., Alfa Laval, GEA, Desmet Ballestra) for food-grade, energy-efficient equipment.

CPO storage (insulated, heated tanks to prevent solidification).

Processing area (equipment arranged for sequential flow).

RBD oil storage (sealed tanks to avoid oxidation).

By-product storage (FFAs, soapstock, spent clay).

Lab (quality testing), offices, and maintenance.

Secure long-term CPO supply contracts with mills or importers to stabilize costs.

Implement quality checks for incoming CPO (test FFA, moisture, carotene content) to adjust refining parameters.

CAPEX: Land, construction, equipment (50–60% of total costs), permits, and initial inventory.

OPEX: CPO (60–70% of OPEX), labor, utilities, maintenance, and RSPO certification fees.

Funding: Explore loans, agribusiness grants, or partnerships with investors (emphasize sustainability for better access to funds).

Hire skilled staff:

Process engineers (oversight of refining).

Lab technicians (quality control: FFA, peroxide value, color).

Operators (equipment handling).

Sustainability officers (to maintain RSPO compliance).

Train teams on safety, RSPO standards, and equipment maintenance.

In-house lab tests:

CPO Incoming: FFA (<5% ideal), moisture (<0.5%), impurities.

RBD Palm Oil: Color (≤3 Red on Lovibond scale), peroxide value (<1 meq/kg), FFA (<0.1%), and RSPO traceability.