Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Expert in Palm Oil Processing Solutions

QIE Machinery

Among all the vegetable oil varieties available in the world, palm oil is the most important. It accounts for a major portion of global vegetable oil consumption. Investment in the palm oil production process has also scaled up to meet this demand.

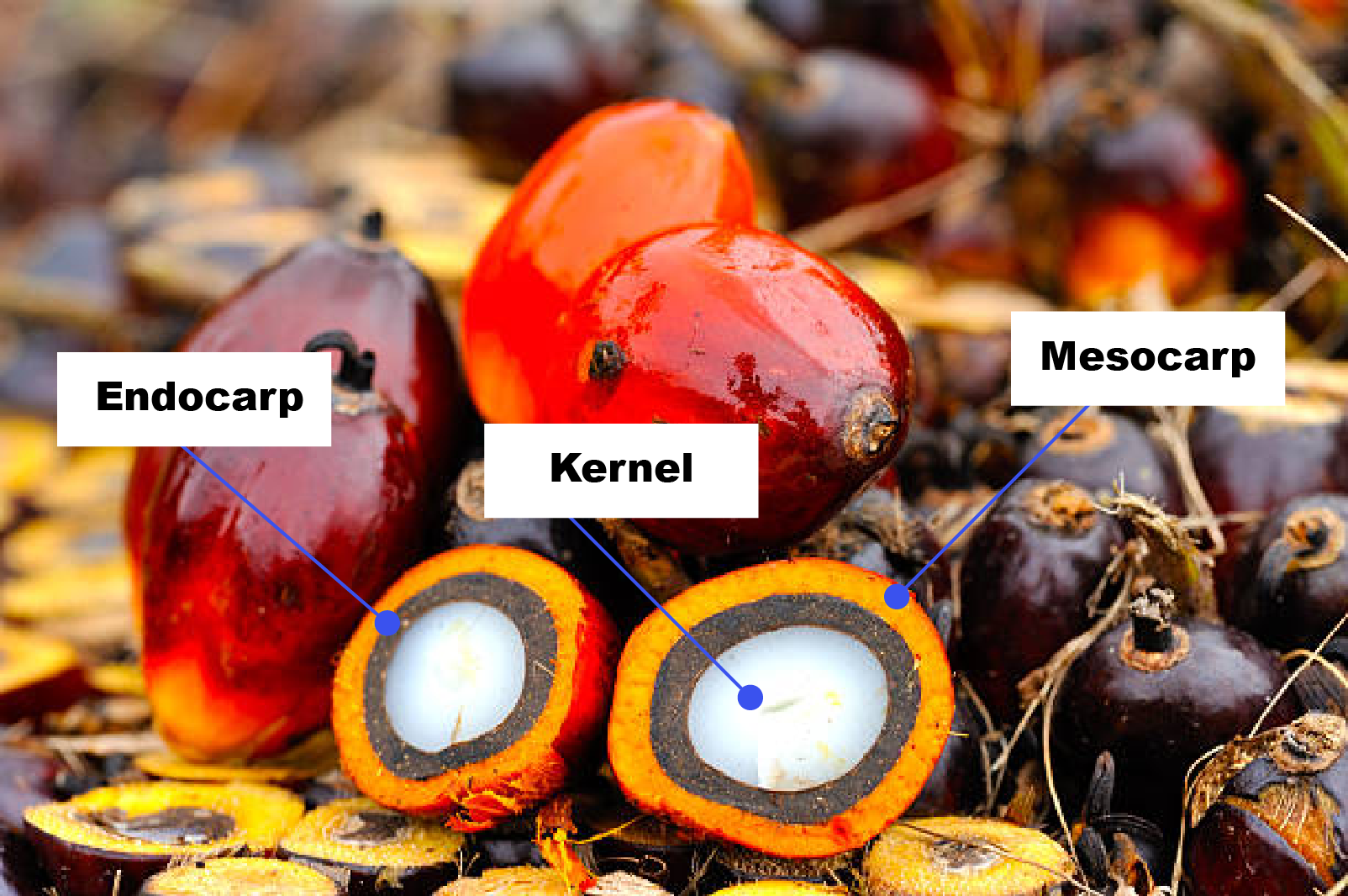

Palm oil is derived from the ripened mesocarp of the fruit of Elaeis guineensis or the oil palm tree. Native to West Africa, oil palms are now extensively cultivated in plantations in Southeast Asia, Latin America, and other regions in the equatorial belt. Today, Indonesia, Malaysia, Thailand, Colombia, and Nigeria are the leading producers of palm oil.

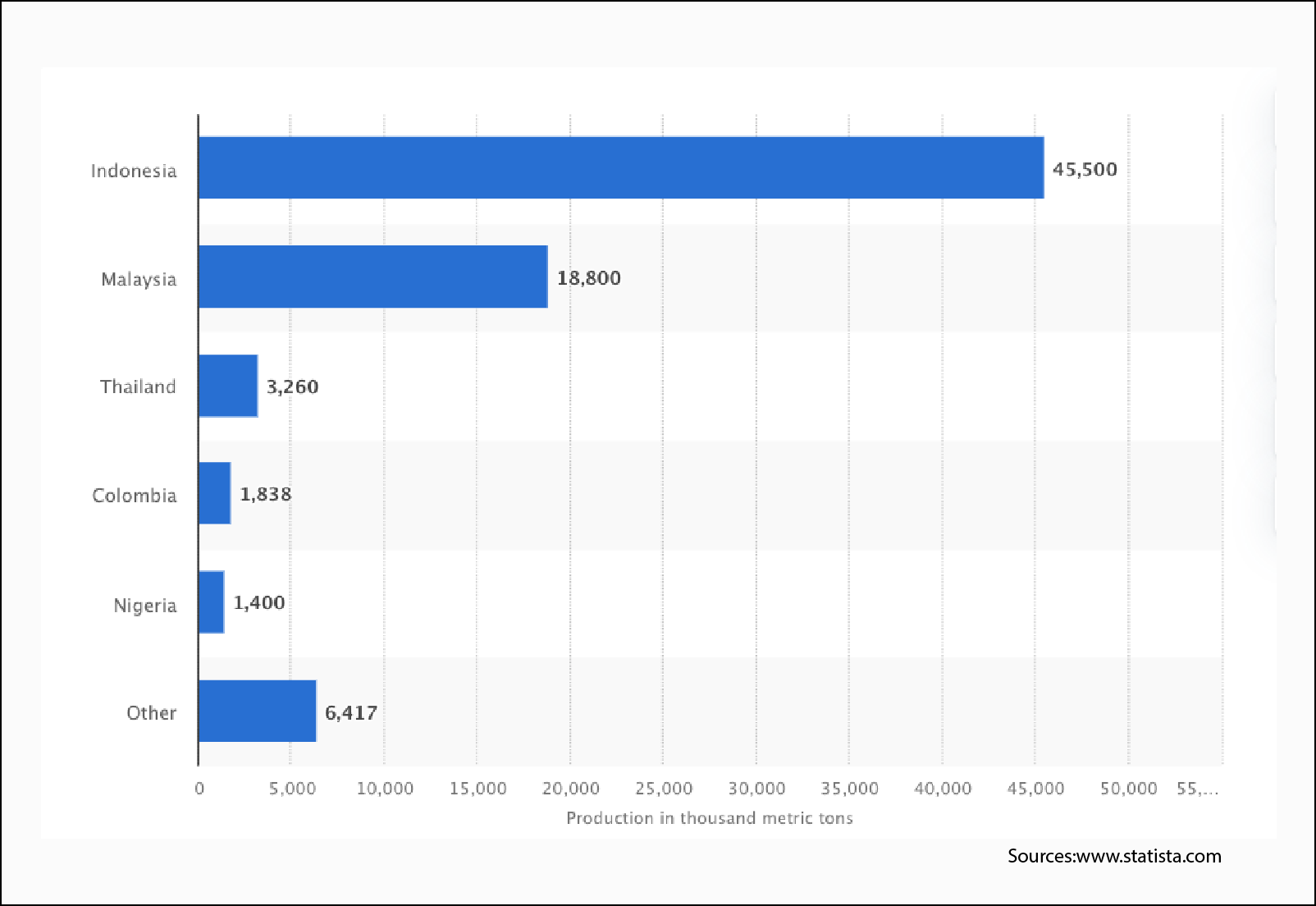

Palm oil trees are cultivated in humid tropical conditions, which can be found 8–10 degrees north and south of the equator. Originally founded in West Africa, the palm oil tree is now found across Asia, Africa, and Latin America to meet global demand. According to Statista,Indonesia is the leading palm oil producer globally, with 45,500 thousand metric tons of production during the years 2022-2023.

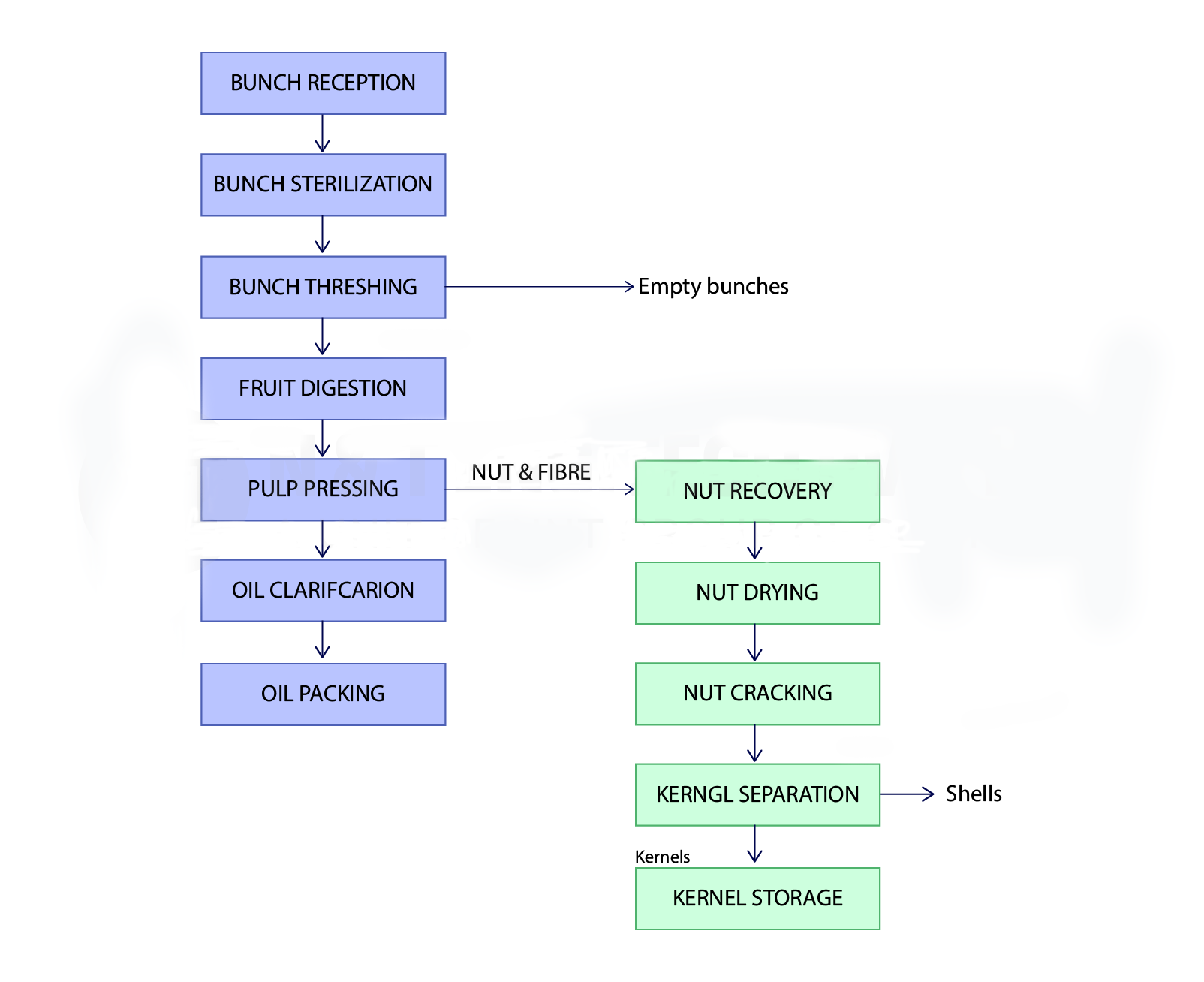

The palm oil production process involves several key steps, starting with harvesting fruit bunches and culminating in the extraction and refining of the oil. These steps include sterilizing the fruit bunches, threshing to separate the fruits, pressing to extract crude palm oil, clarifying the oil, and finally, refining the oil for various uses.

1. Harvesting and Transportation:

Fresh fruit bunches (FFB) are harvested from oil palm trees.

These are then transported to a processing mill.

2. Sterilization:

FFB are sterilized using steam to loosen the fruits from the bunches and inactivate enzymes that can degrade the oil.

This step also helps prevent the buildup of free fatty acids.

3. Threshing:

The sterilized FFB are passed through a threshing machine to separate the palm fruits from the bunches.

This can be done with rotating drums or other automated systems.

4. Digestion and Pressing:

The separated fruits are then heated and mashed in a digester to release the oil.

The mashed fruit is then pressed to extract crude palm oil.

This step often involves high-pressure extraction.

5. Clarification and Drying:

The crude palm oil (CPO) is clarified to remove impurities, such as solid sediments and water.

This may involve settling, filtering, and centrifugation.

The oil is then dried to remove any remaining moisture.

6. Refining:

The clarified and dried CPO can be further refined to produce different grades of palm oil.

This process typically involves degumming, neutralization, bleaching, and deodorization.

Each step aims to remove specific impurities and improve the oil’s quality, color, and stability.

7. Kernel Recovery:

The palm nuts remaining after pressing are processed to recover palm kernels.

These kernels are a source of palm kernel oil, which is a different product from palm oil.

8. Final Products:

Refined palm oil is used in various food products, cosmetics, and industrial applications.

Palm kernel oil is also used in a variety of products, including soaps, detergents, and some foods.

Refinery machines play a pivotal role in the palm oil industry, contributing to the production of high-quality palm oil that meets stringent standards for both domestic and international markets. These machines are essential for the transformation of crude palm oil (CPO) into refined, bleached, and deodorized (RBD) palm oil, which is suitable for a wide range of applications. Hence, here is a table showing machinery used to refine palm oil:

| Name of Machine | Description/Features |

|---|---|

| Neutralizer | A neutralizer works to reduce the free fatty acid (FFA) content in crude palm oil (CPO), improving its quality for various applications. This is achieved through a chemical reaction with an alkaline solution. |

| Bleacher | The bleacher’s role is to remove pigments, impurities, and residual free fatty acids from CPO. It employs adsorbents, like activated clay, to enhance the clarity and appearance of the oil. |

| Deodorizer | The deodorizer is essential for eliminating undesirable odors, off-flavors, and volatile compounds present in CPO. It operates under vacuum conditions to ensure odor removal while preserving oil quality. |

| Clarifier | A clarifier machine separates impurities from oil using gravity settling, contributing to oil purity and clarity. |

| Filtration System | The filtration system removes fine particles and solids from the oil, ensuring it meets quality standards. |

| Heat Exchanger | It helps maintain temperature control during the refining process, ensuring consistent and efficient operation. |

| Deaerator | Removes dissolved gases from the oil, improving stability and shelf life. |

| Steam Generator | A steam generator works as a steaming machine for various refining processes. |

FRACTIONATION

The last step in the palm oil production process is fractionation. Olein, the liquid fraction of palm oil, is used to make cooking oil. Stearin, the solid fraction, is used to make confectionery, shortening, and margarine. To separate these two fractions, the refined oil is cooled under controlled conditions, crystallised, and then the two fractions are separated via filtration.

R&D across disciplines – chemical engineering, mechanical engineering, and biochemistry – has resulted in the development of this complex, effective, and efficient palm oil production process. This process has developed over the years, incorporating higher levels of mechanization, automation, and better oil yields and quality.

This evolution continues – in plantations that aim to enhance their cultivation techniques, at palm oil processing units which prioritise sustainable sourcing, and at our OM Innovation Centre where we commit to making the process as resource-efficient as possible. This evolution is made possible by the interventions of well-meaning governments and the pressures of sustainability-conscious consumers. Each of these stakeholders is an important part of the journey towards a more sustainable palm oil production process – one which results in healthier, happier and safer people and ecosystems.

There are several types of palm oil, each with its own unique characteristics and uses.

Fatty Acid Composition and Health Effects

Palm oil is primarily composed of saturated and monounsaturated fatty acids. The fatty acid profile of palm oil is as follows:

| Fatty Acid | Percentage |

|---|---|

| Palmitic acid (C16:0) | 43.6% |

| Stearic acid (C18:0) | 4.4% |

| Oleic acid (C18:1) | 39.2% |

| Linoleic acid (C18:2) | 10.5% |

| Other fatty acids | 2.3% |

The high saturated fat content of palm oil has raised concerns about its impact on heart health. However, some studies suggest that the saturated fats in palm oil may not be as detrimental as previously thought.